Plate & Sheet Processing

From small custom orders to large production runs of specialty pieces, our metal-working systems do it all with ease and efficiency. Complex shapes and precision machining are no problem for these powerful workhorses. Our full range of finishing capabilities for plate and sheet processing include rolling/shaping of curved surfaces, shearing, welding, and fasteners installation. Other value-added services are available including drilling, tapping, counter-sinking, etc. No matter what the processing needs are for your order, we have the right equipment to get the job done.

Fiber Laser Cutting

The highlight of our production floors is the powerful Amada® ENSIS 4020 Fiber Laser. It’s size capabilities alone make it an instant hit on our production floor, but it’s versatility makes it a real winner. With a massive 9kW power source, this workhorse efficiently cuts a wide range of materials, thick to thin. With an extra large 80” x 120” cutting table, the 4020 easily handles oversize parts. This advanced fiber laser technology delivers unmatched throughput and excellent repeat quality.

This new laser joins our two other fiber laser systems to give Ernest-Spencer outstanding range and capacity in precision metal cutting.

Our production floor features high performance fiber laser cutting machines, operating in both stand-alone and automated workcell configurations. In many cases the finished product is produced entirely on a single machine or within an automated workcell.

80" x repositionable within 240" overall length

Maximum Sheet Size: 80" x 120"

Maximum Material Thickness: 1" Hot Rolled, 1/2" Stainless, 3/8" Aluminum, 5/16" Brass and Copper

Plasma Cutting

Plasma cutting provides near laser-quality cut performance in a more cost efficient process. Larger, thicker plate handling capabilties support heavy component manufacturing.

8' x 40' cutting table

Carbon steel, stainless, and aluminum stock

Cuts up to 4" mild steel with standard oxy fuel cut head, and up to 1.5" with high definition (precision) cut head

Imbedded video camera allows operator to precisely position and monitor the performance of the cutting head

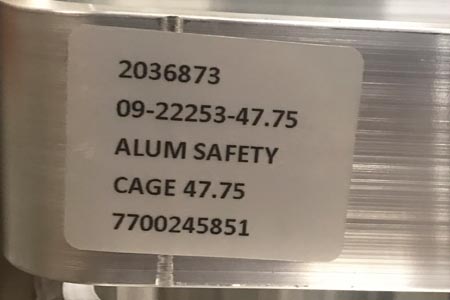

Part Identification

Ernest-Spencer can provide a variety of methods of part identification for serial numbers, inventory management, assembly, traceability and other purposes.

Bar code labels

Permanent adhesive labels

Welded on ID tags

Laser etching

Stamped part numbers